Efficient space management is the cornerstone of productivity in warehouses, offices, moving companies, and even homes. Understanding exactly how much you can store transforms chaos into organized systems.

Whether you’re planning a commercial storage facility, optimizing warehouse layouts, or simply trying to maximize your garage space, accurate volume estimation makes the difference between wasted potential and peak efficiency. Traditional methods of eyeballing capacity or using rough estimates often lead to costly mistakes, overspending on unnecessary space, or worse—running out of room when you need it most.

🎯 Why Accurate Volume Estimates Matter More Than You Think

The financial implications of poor space planning extend far beyond the obvious. Companies lose thousands annually by renting storage facilities larger than necessary or facing emergency overflow costs when underestimating needs. Residential movers consistently struggle with truck size selection, often requiring multiple trips or paying for unused cubic footage.

Accurate volume mapping addresses these challenges head-on. By creating a systematic approach to measuring and calculating storage capacity, you eliminate guesswork and make data-driven decisions. This precision translates directly to cost savings, operational efficiency, and strategic planning advantages that compound over time.

The environmental impact shouldn’t be overlooked either. Optimized space usage reduces the carbon footprint associated with unnecessary transportation, construction of additional storage facilities, and energy consumption from heating or cooling underutilized areas. Sustainability and efficiency go hand in hand when proper volume estimation guides your decisions.

📐 Understanding the Fundamentals of Storage Volume Calculation

Before diving into templates and mapping strategies, grasping the basic principles of volume measurement establishes your foundation. Volume represents three-dimensional space—length multiplied by width multiplied by height. However, real-world storage capacity involves more complexity than simple geometry.

Usable volume differs from gross volume. While a 10x10x10 foot space theoretically offers 1,000 cubic feet, practical storage capacity accounts for access pathways, structural obstacles, irregular shapes, and safety clearances. Industry standards suggest subtracting 20-30% from gross calculations to determine realistic usable capacity.

Key Factors Affecting Storage Capacity

Several variables influence how much you can actually store in any given space. Understanding these factors helps create more accurate templates and estimates that reflect real-world conditions rather than idealized scenarios.

- Ceiling height variations: Not all storage areas maintain consistent height throughout, especially in older buildings or residential spaces with architectural features.

- Structural elements: Columns, beams, HVAC systems, and electrical panels occupy volume that cannot be used for storage.

- Access requirements: Doors, walkways, and clearance zones for equipment operation reduce usable capacity significantly.

- Item characteristics: Irregular shapes, fragile items requiring protective spacing, and stackability limitations affect density.

- Safety regulations: Fire codes, weight distribution limits, and emergency egress requirements impose mandatory constraints.

- Future flexibility needs: Allowing room for reorganization, temporary workspace, or growth prevents premature capacity exhaustion.

🗺️ Creating Your Storage Capacity Mapping Template

A comprehensive mapping template serves as your blueprint for accurate volume estimation. The best templates balance thoroughness with usability, capturing essential data without becoming overwhelming. Your template should adapt to various scenarios while maintaining consistent measurement standards.

Start by establishing standard measurement units across your organization or project. Mixing imperial and metric measurements introduces errors. Choose one system and stick with it throughout your documentation. Most commercial operations in the United States use cubic feet, while international operations typically employ cubic meters.

Essential Components of an Effective Template

Your storage capacity mapping template should include several core elements that work together to provide comprehensive spatial intelligence. These components create a systematic approach that anyone can follow for consistent results.

Space Identification Section: Every mapped area needs clear identification including location name, reference number, date of measurement, and responsible party. This administrative information seems mundane but proves invaluable when managing multiple spaces or tracking changes over time.

Dimensional Data Fields: Record length, width, and height at multiple points if the space is irregular. Include measurements for obstructions, doorways, and access points. Note the smallest clearance dimensions that might limit what can fit through entrances.

Visual Mapping Area: A simple floor plan sketch—even hand-drawn—helps contextualize numerical data. Mark fixed obstacles, indicate primary access routes, and note areas with special considerations like temperature control or weight restrictions.

Capacity Calculations: Break down gross volume, adjustment factors, and net usable volume. Show your work so others can verify calculations or adapt them for different storage methods or item types.

📊 Implementing Volume Estimation Best Practices

Templates only work when paired with solid measurement and estimation practices. Developing consistent methodologies ensures reproducible results regardless of who performs the assessment. These practices separate amateur approaches from professional-grade capacity planning.

Always measure spaces when empty or as close to empty as possible. Existing clutter obscures true dimensions and makes accurate assessment nearly impossible. If measuring occupied space, temporarily clear sections and extrapolate measurements rather than guessing around obstacles.

Technology Tools That Enhance Accuracy

Modern technology dramatically improves measurement precision and speeds up the mapping process. Laser distance measurers eliminate tape measure errors and enable single-person operation in large spaces. These devices typically cost between $30 and $200 depending on features and accuracy levels.

Digital room scanners and 3D mapping apps transform smartphones into sophisticated measurement tools. Some applications use augmented reality to calculate room dimensions and volumes with remarkable accuracy. For professional operations handling multiple properties or complex spaces, these tools quickly justify their cost through time savings and improved precision.

Building Information Modeling (BIM) software represents the cutting edge for commercial and industrial applications. While requiring significant investment in both software and training, BIM systems provide comprehensive spatial management capabilities that integrate capacity planning with architectural, mechanical, and operational systems.

💡 Advanced Mapping Strategies for Complex Spaces

Standard rectangular rooms present straightforward mapping challenges, but real-world storage often involves irregular shapes, multi-level structures, or specialized environments. Advanced strategies address these complexities while maintaining the accuracy essential for reliable volume estimates.

Divide irregular spaces into geometric sections that can be calculated separately and summed. A warehouse with an L-shape becomes two rectangles. A room with a sloped ceiling divides into rectangular and triangular prism sections. This segmentation approach maintains mathematical accuracy while simplifying individual calculations.

Accounting for Vertical Storage Optimization

Many operations underutilize vertical space, focusing capacity calculations primarily on floor area. Sophisticated mapping templates incorporate vertical zoning strategies that recognize different capacity characteristics at various heights.

Low zones (0-4 feet) typically accommodate highest-density storage with easiest access. Medium zones (4-8 feet) balance accessibility and capacity. High zones (8+ feet) offer significant volume but require equipment for access and pose retrieval time considerations. Your template should calculate capacity for each zone separately, enabling strategic placement decisions that match item characteristics to optimal storage heights.

| Height Zone | Access Method | Ideal Item Types | Capacity Efficiency |

|---|---|---|---|

| 0-4 feet | Direct hand access | Frequently used items, heavy objects | 90-95% |

| 4-8 feet | Step stool, short ladder | Medium-frequency items, moderate weight | 80-85% |

| 8-12 feet | Ladder, forklift | Rarely accessed, long-term storage | 70-75% |

| 12+ feet | Specialized equipment | Archived items, seasonal stock | 60-70% |

🔧 Customizing Templates for Specific Storage Scenarios

One-size-fits-all templates rarely deliver optimal results across diverse storage applications. Customization adapts your mapping approach to specific industry requirements, item characteristics, and operational workflows. The investment in developing scenario-specific templates pays dividends in accuracy and usability.

Warehouse and distribution center templates emphasize pallet positions, forklift aisle widths, and rack configuration options. These environments require precise calculations of selectivity versus density trade-offs and often incorporate weight capacity alongside volume measurements.

Residential and Moving Applications

Home organization and moving scenarios benefit from templates that account for furniture dimensions, box standardization, and room-by-room inventories. Unlike commercial storage, residential applications must balance capacity optimization with livability and aesthetic considerations.

Moving companies particularly value templates that translate room contents into truck volume requirements. Including standard moving box volumes and common furniture cubic footage in your template streamlines the estimation process. A typical bedroom might contain 150-250 cubic feet of belongings, while living rooms range from 300-600 cubic feet depending on furnishings.

Specialized Environment Considerations

Climate-controlled storage, cold storage, and hazardous material facilities require templates incorporating regulatory spacing requirements and environmental system limitations. These specialized templates account for larger safety buffers, segregation requirements, and reduced effective capacity due to mandatory clearances.

Archive and document storage demands different capacity calculations based on box standardization, retrieval system requirements, and long-term stability considerations. These applications often prioritize accessibility and organization over maximum density.

📈 Analyzing and Optimizing Based on Mapping Data

Creating accurate volume estimates represents only the first step. The true value emerges when you analyze mapping data to identify optimization opportunities and make informed strategic decisions. Systematic analysis transforms raw capacity numbers into actionable intelligence.

Compare actual utilization against mapped capacity to calculate efficiency metrics. Many operations discover they’re using only 60-70% of available capacity due to poor organization, inappropriate storage methods, or failure to leverage vertical space. These insights drive improvement initiatives that deliver measurable ROI without facility expansion.

Continuous Improvement Through Remapping

Storage needs evolve over time as inventory mixes change, business grows, or operational priorities shift. Establishing a regular remapping schedule—annually for static environments, quarterly for dynamic operations—keeps your capacity intelligence current and highlights trends before they become problems.

Document changes between mapping cycles to understand capacity consumption rates and forecast future needs. This historical data enables proactive planning rather than reactive crisis management when space runs short.

⚠️ Common Mapping Mistakes and How to Avoid Them

Even experienced professionals fall into predictable traps when creating storage capacity maps. Awareness of these common mistakes helps you implement preventive measures and quality checks that maintain estimation accuracy.

The most frequent error involves ignoring or minimizing the space required for circulation and access. Theoretical capacity calculations that pack every cubic foot with storage invariably fail in practice when workers cannot actually reach stored items. Always incorporate realistic aisle widths and working space into your calculations.

Another widespread mistake stems from assuming uniform stackability across different item types. Not everything can be stacked to the ceiling, and weight distribution limits often restrict practical stacking heights well below structural capabilities. Your template should include fields for maximum stack heights specific to contents rather than applying blanket assumptions.

Verification and Quality Control

Implement a verification process where a second person reviews measurements and calculations before finalizing capacity estimates. Simple arithmetic errors or transposed dimensions can throw off entire projects. This quality check costs minimal time but prevents expensive mistakes.

For critical applications, consider performing test loads in a small section of mapped space. Actually arranging items according to your plan quickly reveals any calculation errors or impractical assumptions before committing to full-scale implementation.

🚀 Future-Proofing Your Storage Capacity Strategy

Effective capacity mapping extends beyond current needs to anticipate future requirements and changing circumstances. Building flexibility into your templates and planning processes protects against rapid obsolescence and costly retrofits.

Include fields in your template for planned changes, expansion possibilities, and alternative configuration scenarios. Documenting not just what exists but what could be enables rapid response when circumstances change. Note where walls could be removed, ceilings raised, or storage systems upgraded to increase capacity.

Consider modular storage solutions that can be reconfigured as needs evolve. Your capacity mapping should account for this flexibility, calculating capacity under multiple configuration scenarios. This approach maximizes long-term value from storage investments while maintaining adaptability.

💼 Professional Applications and Industry Standards

Various industries have developed specialized capacity mapping standards that incorporate sector-specific requirements and best practices. Aligning your templates with recognized industry standards facilitates communication with partners, ensures regulatory compliance, and leverages collective expertise.

The logistics industry commonly uses NFPA (National Fire Protection Association) guidelines for warehouse capacity and spacing requirements. Cold storage follows IIAR (International Institute of Ammonia Refrigeration) standards. Document management adheres to ARMA International specifications. Research relevant standards for your specific application to ensure your templates meet professional expectations.

Professional certifications in space planning, warehouse management, and facilities management provide structured education in capacity mapping methodologies. These credentials signal expertise to clients and employers while ensuring practitioners stay current with evolving best practices.

🎓 Training Teams to Use Mapping Templates Effectively

The best template in the world delivers poor results if users don’t understand proper application. Investing in training ensures consistent, accurate implementation across your organization and maximizes the return on your template development efforts.

Develop clear standard operating procedures (SOPs) that walk users through the mapping process step-by-step. Include visual examples, common scenarios, and troubleshooting guidance. Video tutorials demonstrating proper measurement techniques prove particularly effective for visual learners and serve as reference material when questions arise.

Pair new team members with experienced mappers for their first few projects. This mentorship approach transfers tacit knowledge that written procedures cannot fully capture while building confidence and competence simultaneously.

🌟 Transforming Space Challenges Into Strategic Advantages

Organizations that master storage capacity mapping gain competitive advantages extending well beyond simple space efficiency. Accurate volume estimation enables confident capacity commitments to customers, optimized lease negotiations with landlords, and data-driven expansion decisions that align perfectly with growth trajectories.

The discipline of systematic mapping cultivates organizational habits of measurement, documentation, and continuous improvement. These cultural elements compound over time, elevating operational excellence across all business functions, not just storage management.

Start small if comprehensive mapping seems overwhelming. Choose one critical area, develop and refine your template through that pilot project, then expand systematically. The journey from space chaos to optimized capacity begins with a single measurement and the commitment to systematic improvement.

Your storage capacity mapping template becomes a living document that evolves with your needs, incorporating lessons learned and adapting to new challenges. This iterative refinement process ensures your approach stays relevant and valuable regardless of how your storage requirements change over time. Embrace the discipline of accurate volume estimation and watch scattered spaces transform into strategic assets delivering measurable value.

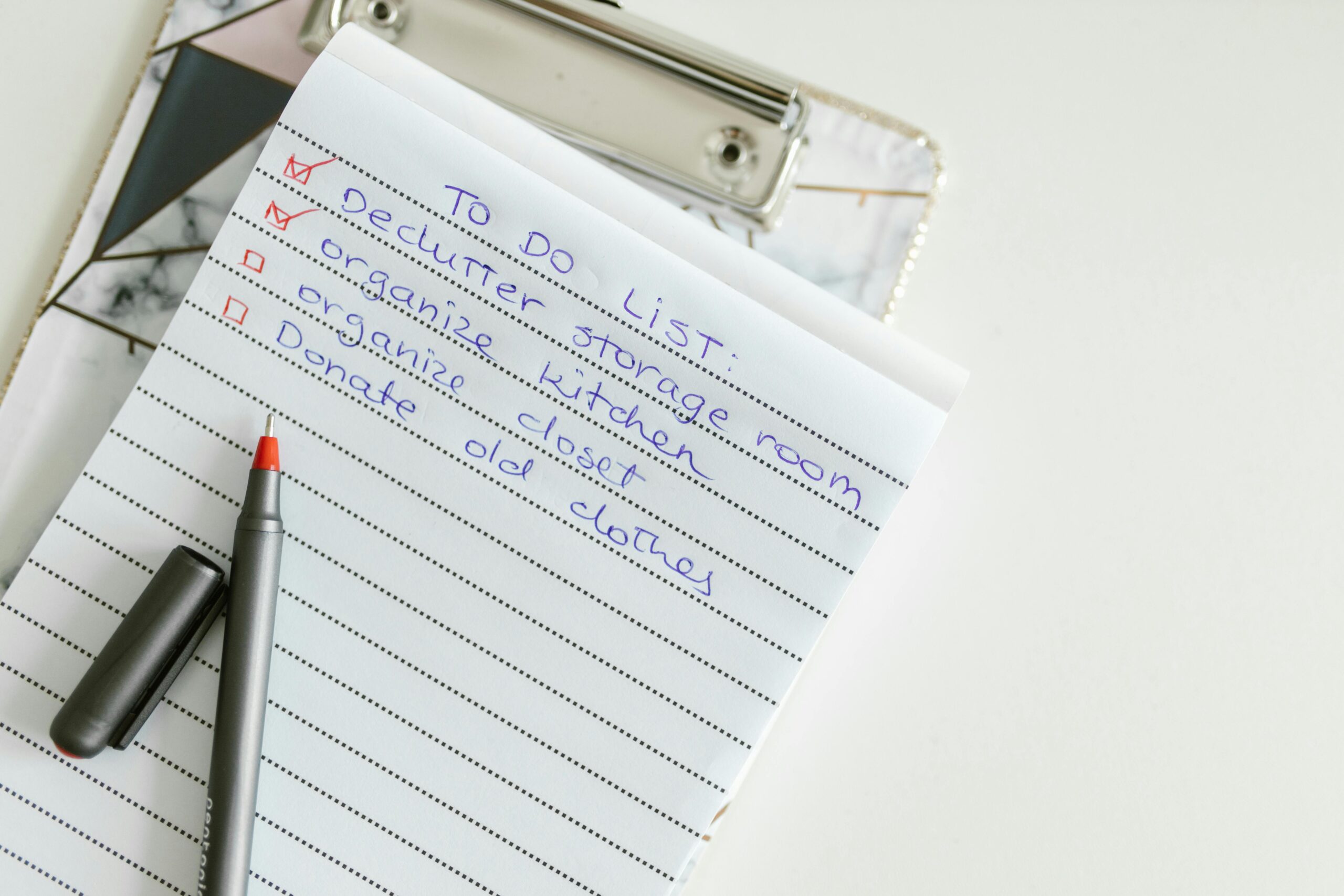

Toni Santos is a home organization specialist and kitchen workflow consultant specializing in the design of decluttering systems, meal-prep station workflows, and spatial planning frameworks. Through a practical and visually-focused lens, Toni investigates how households can optimize storage, streamline culinary routines, and bring order to living spaces — across kitchens, cabinets, and everyday environments. His work is grounded in a fascination with spaces not only as structures, but as carriers of functional meaning. From decluttering checklists to meal-prep stations and space mapping templates, Toni uncovers the organizational and visual tools through which households maintain their relationship with clarity and efficiency. With a background in spatial design and home organization systems, Toni blends visual planning with practical research to reveal how storage solutions are used to shape function, preserve order, and optimize daily routines. As the creative mind behind xynterial.com, Toni curates illustrated checklists, workflow diagrams, and organizational templates that strengthen the essential connection between space planning, kitchen efficiency, and thoughtful storage design. His work is a tribute to: The functional clarity of Decluttering Checklists and Systems The streamlined design of Meal-Prep Station Workflows and Layouts The spatial intelligence of Space Mapping and Floor Plans The organized versatility of Storage Solutions by Cabinet Type Whether you're a home organizer, kitchen designer, or curious seeker of clutter-free living wisdom, Toni invites you to explore the hidden potential of organized spaces — one checklist, one cabinet, one workflow at a time.