Maintaining an organized space shouldn’t feel like a constant battle. Whether you’re managing a bustling warehouse, a home office, or a classroom, effective cabinet labeling systems transform chaos into calm with minimal ongoing effort.

The right labeling solution does more than simply identify contents—it creates a visual language that anyone can understand instantly. When labels withstand daily wear, environmental challenges, and the test of time, they become invisible infrastructure that quietly supports productivity without demanding constant maintenance or replacement.

🏆 Why Durability Matters in Cabinet Labeling Systems

Temporary labels create permanent headaches. When labels fade, peel, or fall off, they don’t just disappear—they leave behind confusion, wasted time, and the frustration of repeatedly redoing the same organizational work. A durable labeling system is an investment that pays dividends in efficiency every single day.

Professional environments particularly benefit from labels that maintain their appearance and readability over years rather than months. In medical facilities, manufacturing plants, educational institutions, and commercial kitchens, label failure can mean more than inconvenience—it can compromise safety, compliance, and operational efficiency.

The Hidden Costs of Poor-Quality Labels

Consider the cumulative impact of labels that don’t last. Each failed label represents time spent searching for items, interruptions to workflow, decreased productivity, and the labor cost of creating replacement labels. Multiply this across dozens or hundreds of cabinets, and the true expense of cheap labeling solutions becomes staggering.

Beyond direct costs, inadequate labeling affects workplace morale. Staff members become frustrated when organizational systems break down, leading to decreased job satisfaction and potentially higher turnover in roles that depend heavily on efficient material access and inventory management.

🔍 Essential Characteristics of Long-Lasting Cabinet Labels

Not all labels are created equal. The difference between a label that lasts six months and one that remains legible for five years often comes down to specific material properties and construction techniques that aren’t immediately obvious when making purchasing decisions.

Material Selection Makes the Difference

Vinyl labels offer exceptional durability compared to paper alternatives, resisting moisture, oils, and temperature fluctuations that quickly destroy paper-based solutions. Laminated labels add an extra protective layer that guards against scratches, UV exposure, and chemical exposure common in industrial and commercial settings.

Metal labels provide unparalleled longevity in harsh environments, though they come with higher upfront costs. Anodized aluminum labels resist corrosion, extreme temperatures, and physical abuse while maintaining readability for decades. These prove particularly valuable in outdoor applications, industrial facilities, and areas subject to cleaning with harsh chemicals.

Adhesive Technology That Actually Sticks

The most beautiful label becomes worthless if the adhesive fails. Industrial-grade adhesives form permanent bonds with cabinet surfaces without leaving residue when removal eventually becomes necessary. These adhesives cure over time, actually strengthening their hold during the first 24-48 hours after application.

Temperature-resistant adhesives maintain their grip through seasonal fluctuations, preventing the common problem of labels lifting at corners and edges. In refrigerated or heated environments, specialized adhesive formulations ensure labels remain firmly attached despite conditions that would cause standard adhesives to fail immediately.

📋 Choosing the Right Labeling System for Your Space

Different environments demand different labeling approaches. A solution perfect for a climate-controlled office might fail spectacularly in a warehouse, while industrial-grade labels might represent unnecessary expense for low-traffic residential applications.

Assessing Your Specific Needs

Begin by evaluating environmental factors. Consider temperature ranges, humidity levels, exposure to cleaning chemicals, UV light exposure, and the likelihood of physical contact or abrasion. Honest assessment of these factors guides you toward appropriate materials and construction methods.

Traffic volume significantly impacts label longevity. High-touch cabinets in busy commercial kitchens require more durable solutions than rarely-accessed storage in a home basement. Similarly, public-facing storage needs labels that resist tampering and vandalism beyond what’s necessary for staff-only areas.

Print Method Considerations

Thermal transfer printing creates labels with exceptional fade resistance compared to inkjet or laser printing. The heat-bonded images withstand UV exposure, chemical contact, and abrasion that quickly degrade conventionally printed labels. For critical applications requiring decades of readability, thermal transfer represents the gold standard.

Direct thermal printing offers convenience for temporary applications, but printed images darken and become illegible over time, especially with heat exposure. This technology suits shipping labels and short-term identification but fails dramatically for permanent cabinet organization systems.

🎨 Design Principles for Maximum Effectiveness

Durability means nothing if labels aren’t readable and useful. Thoughtful design transforms simple identification tags into powerful organizational tools that reduce cognitive load and accelerate task completion.

Typography That Communicates Clearly

Sans-serif fonts provide superior readability at various distances and lighting conditions. Avoid decorative typefaces that sacrifice legibility for aesthetic appeal. Font size should accommodate the typical viewing distance—larger for high-mounted cabinets, potentially smaller for eye-level installations.

High contrast between text and background ensures readability even in suboptimal lighting. Black text on white or yellow backgrounds provides maximum legibility, while color coding can add an additional layer of organizational information without compromising clarity.

Strategic Use of Color Coding

Color systems accelerate visual searching when implemented thoughtfully. Assign colors by category, department, priority level, or frequency of use—whatever division makes most sense for your specific application. Consistency across your entire space makes the system intuitive and self-teaching.

Limit your color palette to prevent confusion. Five to seven distinct colors typically represent the maximum number most people can quickly distinguish and remember. More colors dilute the system’s effectiveness and create cognitive overload rather than clarity.

🛠️ Implementation Strategies for Lasting Results

Even the highest-quality labels fail when improperly applied. Surface preparation, application technique, and environmental conditions during installation dramatically impact long-term performance.

Proper Surface Preparation

Clean surfaces thoroughly with isopropyl alcohol or appropriate cleaners to remove oils, dust, and residues that prevent adhesive bonding. Allow surfaces to dry completely—moisture trapped beneath labels creates eventual failure points where labels lift and peel.

Room temperature application yields best results. Adhesives perform poorly when applied in extreme cold or heat. When working in non-ideal environments, pre-conditioning labels and allowing them to reach room temperature before application improves outcomes significantly.

Application Techniques for Professional Results

Apply firm, even pressure across the entire label surface, working from center outward to prevent air bubble formation. For larger labels, use a squeegee or credit card edge to ensure complete contact between adhesive and cabinet surface.

Allow adhesive cure time before subjecting labels to stress. Avoid cleaning around newly applied labels for at least 24 hours, and minimize physical contact during the initial curing period when adhesive bonds strengthen and reach full holding power.

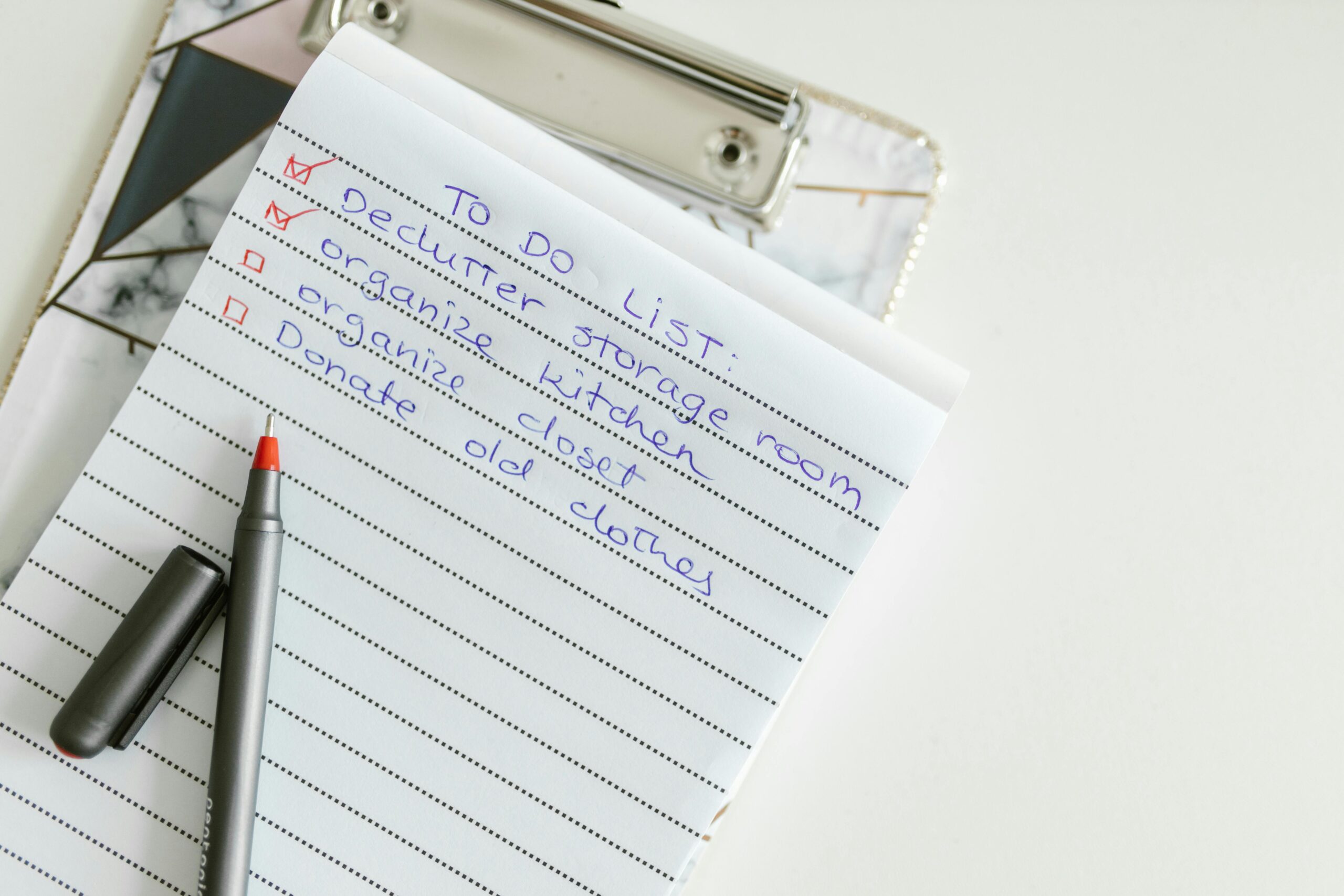

💡 Advanced Organization Techniques

Labels form the foundation, but combining them with complementary systems creates organizational synergy that multiplies effectiveness beyond what simple identification alone achieves.

Integrating QR Codes and Smart Technology

QR code labels bridge physical organization with digital inventory systems. Scanning codes instantly accesses detailed information about cabinet contents, maintenance schedules, reorder points, or usage instructions—information that wouldn’t fit on traditional labels.

Smart label systems with NFC technology enable touchless information access and automated inventory tracking. While representing higher initial investment, these systems dramatically reduce labor costs in large facilities with extensive cabinet infrastructure requiring regular inventory management.

Hierarchical Labeling Systems

Multi-level labeling creates increasingly specific identification as users move closer to items. Room or zone labels provide high-level navigation, cabinet labels narrow the search field, and interior shelf or bin labels pinpoint exact locations within larger storage units.

This hierarchical approach mirrors how people naturally search for items, supporting intuitive navigation that requires minimal training. New staff members, temporary workers, and occasional users all benefit from systems that guide them progressively toward needed items.

🔧 Maintenance and Longevity Maximization

Even durable labels benefit from minimal maintenance that extends their useful life and maintains professional appearance throughout years of service.

Cleaning Best Practices

Regular gentle cleaning prevents buildup that can obscure text and degrade label materials over time. Use soft cloths with mild cleaners appropriate for label materials—harsh chemicals and abrasive tools damage protective coatings and accelerate deterioration.

Establish cleaning schedules based on environmental conditions. High-dust environments require more frequent attention than climate-controlled offices, while areas exposed to cooking grease or industrial residues need specialized cleaning approaches that remove contaminants without damaging labels.

Periodic System Audits

Schedule quarterly or annual reviews of your labeling system to identify failures before they compromise organizational effectiveness. Early detection of lifting corners, fading text, or damaged labels allows proactive replacement rather than reactive scrambling when labels fail completely.

These audits also provide opportunities to refine your organizational system based on actual usage patterns. Cabinets accessed more frequently than anticipated might benefit from enhanced labeling, while rarely-used storage might be reorganized or consolidated.

📊 Comparing Popular Labeling Solutions

Understanding the strengths and limitations of different labeling technologies helps match solutions to specific requirements without overspending on unnecessary features or underinvesting in critical durability.

| Label Type | Durability | Cost | Best Applications |

|---|---|---|---|

| Paper Labels | 6-12 months | Low | Temporary organization, low-traffic residential |

| Laminated Vinyl | 3-5 years | Moderate | Commercial offices, schools, moderate environments |

| Industrial Vinyl | 5-10 years | Moderate-High | Warehouses, manufacturing, high-traffic commercial |

| Anodized Metal | 10+ years | High | Outdoor storage, harsh industrial, permanent installations |

| Engraved Plastic | 8-15 years | Moderate-High | Medical facilities, laboratories, chemical exposure areas |

🌟 Real-World Success Stories

Theory meets practice when examining how organizations have transformed their efficiency through thoughtful implementation of durable labeling systems.

Manufacturing Facility Transformation

A mid-sized automotive parts manufacturer reduced tool location time by 67% after replacing paper labels with industrial-grade vinyl throughout their 50,000 square foot facility. The project paid for itself within four months through increased productivity, and labels remain fully legible five years later with zero replacements needed.

The company credits color-coded departmental systems and clear hierarchical navigation for enabling new employees to achieve full productivity weeks faster than before the labeling upgrade. Reduced training time and improved safety compliance created benefits far beyond the immediate organizational improvements.

Educational Institution Case Study

A university laboratory complex serving 2,000 students implemented engraved plastic labels with QR code integration linking to digital inventory databases. The system reduced equipment loss by 89% and virtually eliminated safety incidents related to improperly stored chemicals.

Eight years after installation, 98% of original labels remain in service with no degradation in readability. The university estimates the system has saved over $120,000 in replaced equipment and prevented countless hours of staff time searching for misplaced items.

🚀 Future-Proofing Your Organization System

The best labeling systems accommodate growth and change without requiring complete reinstallation. Building flexibility into your organizational infrastructure ensures longevity beyond individual label lifespans.

Modular Design Approaches

Standardized label sizes and consistent placement schemes allow easy updates when cabinet contents change. Using label holders or magnetic backing enables quick swaps without adhesive removal, preserving cabinet finishes while maintaining organizational accuracy.

Digital design templates ensure visual consistency when creating new labels years after initial installation. Maintaining design files with exact specifications for fonts, colors, sizes, and layouts prevents the gradual drift that creates visually chaotic systems over time.

Scalability Considerations

Choose systems that can expand as your space grows. Whether adding new cabinets to existing rooms or extending organization to additional facilities, consistent labeling approaches create familiarity that reduces confusion and maintains efficiency across all locations.

Document your organizational logic and labeling standards in accessible formats. When staff turnover occurs or expansion projects begin, clear documentation ensures new implementations match existing systems rather than creating confusing variations that undermine the entire organizational structure.

🎯 Making the Investment Decision

Quality labeling systems require upfront investment that can seem substantial compared to basic paper labels. However, total cost of ownership over five to ten years reveals that durable solutions actually cost less while delivering superior performance.

Calculating Return on Investment

Consider time savings multiplied across all users over the system’s lifetime. If 20 employees each save just 5 minutes daily through improved organization, that’s 100 employee-minutes saved every day. Over a year, this represents nearly 400 hours of productivity—easily justifying even premium labeling solutions.

Factor in replacement costs for failed labels. Creating and installing replacement labels requires labor, materials, and workflow interruption. Durable labels that last five to ten times longer than cheap alternatives typically cost less than twice as much, representing substantial lifetime savings.

✨ Creating Systems That Work Effortlessly

The ultimate goal of any organizational system is becoming invisible—working so seamlessly that users rarely think about it consciously. When cabinets are labeled durably and clearly, finding items becomes automatic, freeing mental energy for more valuable tasks.

Effortless organization isn’t about perfection; it’s about creating systems robust enough to handle real-world use without constant intervention. Durable labels that withstand years of daily interaction become part of the physical infrastructure, as reliable and unnoticed as walls and floors.

By investing thoughtfully in labeling systems designed to stand the test of time, you’re not just organizing cabinets—you’re building efficiency into the fundamental structure of your space. This efficiency compounds daily, delivering returns that far exceed the initial investment while creating environments where productivity flourishes naturally.

Whether organizing a single room or an entire facility, the principles remain constant: choose materials suited to your environment, design for clarity and usability, implement with attention to detail, and maintain minimally. The result is organization that truly works effortlessly, year after year.

Toni Santos is a home organization specialist and kitchen workflow consultant specializing in the design of decluttering systems, meal-prep station workflows, and spatial planning frameworks. Through a practical and visually-focused lens, Toni investigates how households can optimize storage, streamline culinary routines, and bring order to living spaces — across kitchens, cabinets, and everyday environments. His work is grounded in a fascination with spaces not only as structures, but as carriers of functional meaning. From decluttering checklists to meal-prep stations and space mapping templates, Toni uncovers the organizational and visual tools through which households maintain their relationship with clarity and efficiency. With a background in spatial design and home organization systems, Toni blends visual planning with practical research to reveal how storage solutions are used to shape function, preserve order, and optimize daily routines. As the creative mind behind xynterial.com, Toni curates illustrated checklists, workflow diagrams, and organizational templates that strengthen the essential connection between space planning, kitchen efficiency, and thoughtful storage design. His work is a tribute to: The functional clarity of Decluttering Checklists and Systems The streamlined design of Meal-Prep Station Workflows and Layouts The spatial intelligence of Space Mapping and Floor Plans The organized versatility of Storage Solutions by Cabinet Type Whether you're a home organizer, kitchen designer, or curious seeker of clutter-free living wisdom, Toni invites you to explore the hidden potential of organized spaces — one checklist, one cabinet, one workflow at a time.